Connect With Our Team

Get In TouchConnect With Our Team

Get In Touch Inside the Lab

Inside the Lab

The tile grading will be a critical pointer of quality, since it will enable consumers to make quality decisions depending on durability, aesthetic value, and appropriateness of the tiles. Tiles are rated by a numerical system that shows the quality and the thickness.

The best quality tiles are grade 1, which do not have discernible flaws. Such tiles are generally 3/4-inch thick and have very good strength, uniformity and a good finish. These products can be used in any location, such as high-traffic floors and walls.

The Grade 2 tiles have slight imperfections, which make them structurally fit, though. They measure about 1/2-inch in thickness and are thus suitable for residential use in floors as well as walls, where average performance is being entertained.

The lowest grade, Grade 3, tiles are typically 1/4inch thin and can only be used on walls because it was not built to withstand considerable wear.

These are also called Standard (Grade 1), Secondary (Grade 2) and Cull Grade (Grade 3) tiles. Our manufacturing unit thoroughly inspects every tile and thus grades them in accordance with its surface finish, consistency of size, uniformity of colour and strength, which gives assurance to our customers of the quality they can believe in.

Scratch resistance and wear rating are the main features that indicate how durable a tile can be in heavy traffic areas. The Porcelain Enamel Institute (PEI) rating is the measure of a glazed tile's resistance to abrasion under daily wear and tear. The more the PEI number (represented in Roman numerals), the more efficient the classification of the tile under foot traffic. PEI-rated tiles I and II can only be used on light-duty areas, while tiles III fit flooring niches in homes. PEI IV tiles are advisable to apply in the places where traffic is heavy in residential and low-level commercial environments, whereas PEI V should be applied in heavy-duty commercial projects.

Also, the property of scratch resistance is determined by the so-called Mohs hardness scale 1 (softer) to 10 (harder). A tile that has a Mohs scale of 7 or higher is very effective against scratches and therefore suitable for places that experience high traffic. At our plant, all tiles are thoroughly checked to conform to these standards of long-wear, protection against scratching and durability.

The water absorption rating of the tile is a major parameter to determine the aptness of the tile in various climate conditions and especially wet or outdoor. The rating is based on the water absorbency amount compared to the weight of a tile. Tiles are Nonvitreous (absorbs more than 7 percent), semi-vitreous, vitreous and impervious (absorbs less than 0.5 percent). The nonvitreous tiles cannot be used in areas that have a lot of moisture, such as in a shower, and the vitreous and impervious tiles work best in a wet environment, such as a bathroom, kitchen, or patio.

The absorption test is done by the exposure of tiles to dyed standing water under a 16-hour exposure time, and the moisture penetration is checked. Further, to make sure that the tiles will last in a freezing environment, the tiles also go through a frost resistance test that tests and rates how well the tiles can handle repeated freeze and thaw periods without cracking. We test every tile at our premises to ensure solid performance in water absorption and frost resistance.

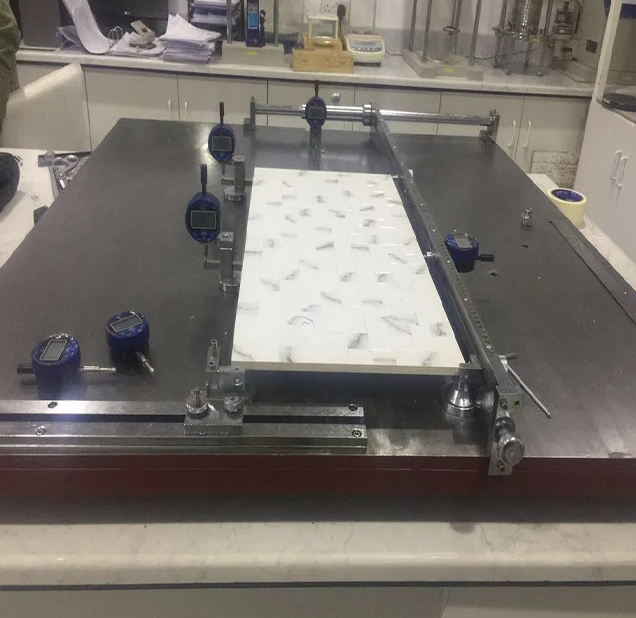

The Flatness Surface Test is essential in the ceramic tile industry to ensure that each tile has a uniform and even surface, which is critical for proper installation and a seamless visual finish. Lippage, uneven grout lines and unstable flooring are possible problems with tiles that have irregularities on the surface of their tile (warping, bowing, bending). Such flaws not only kill the aesthetic aspect, but there are chances of getting involved in matters that relate to safety when the object is being installed. At our facility, we use precision instruments that measure the flatness of the tile surface. The tiles that pass the test of very precise tolerance are only approved due to the high possibility of being fitted correctly, structurally sound and of highly uniform quality appearance.

Stain Test is an index that determines how a tile reacts to stains caused by the most common substances in the household: coffee, oil, a mark of ink, or food stains. The tiles are subjected to the possible staining reagents for a certain period and then inspected as to the simplicity of cleaning and remaining staining. Our glaze recipes are high-performance, which makes our tiles easy to care for, and even after years of use in the kitchen, bathroom, and other high-traffic regions, they still have their original beauty.

The Whiteness Test determines the brightness and purity of white or light-colored tiles. A high degree of whiteness reflects superior raw materials and controlled firing processes. A good level of whiteness is evidence of quality raw materials and adequately regulated firing. We determine the level of whiteness by assessing the darkness and brightness using a calculated scale based on a modified light reflection technique on each batch to maintain a similar, clean and lively look. The test plays an important role in applications whose clarity of message and colour shades are vital, including modern interior and minimalist designs.

The Color Accuracy test focuses on tones and shades of the tile to be correct by the design requirements and should also be the same throughout all the batches. We put the visual inspection under spectrophotometric equipment to check the accuracy of colors against sample tiles or design mock-ups. It is necessary to carry out this test to ensure harmony in any big project where tiles need to blend in terms of tone, i.e., matte, glossy, textured, etc.

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to inquiry@asianoceramic.com

|

Mehul Vasoya 0091 95105 63767 |

|

Dhaval Detroja 0091 97127 38883 |